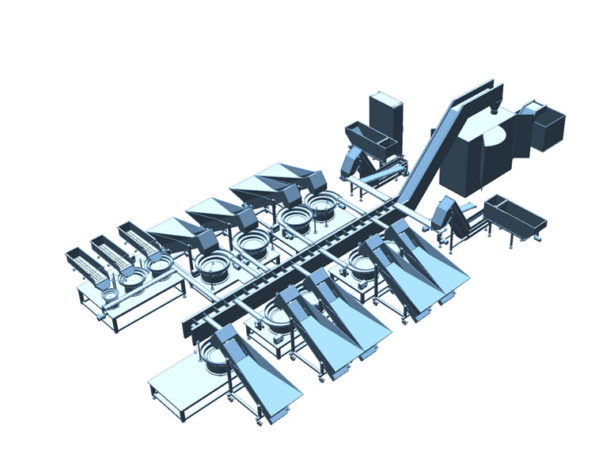

The Solution

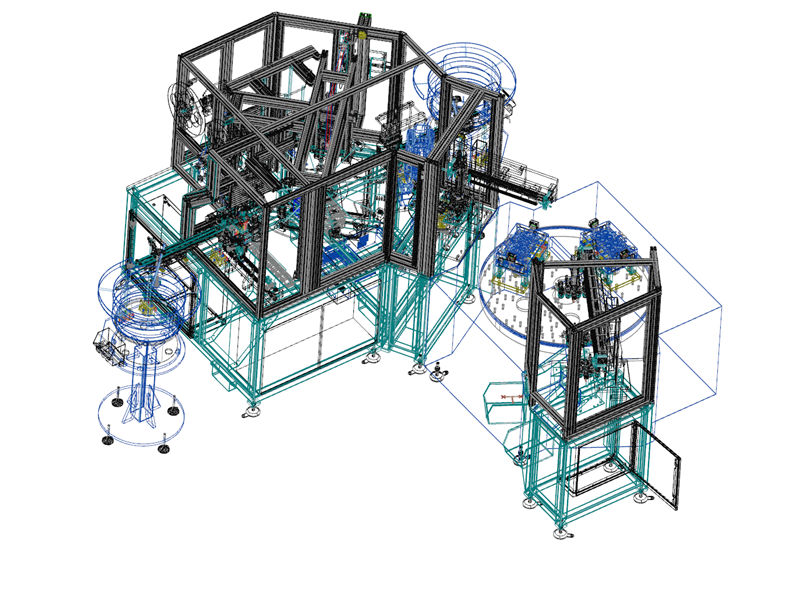

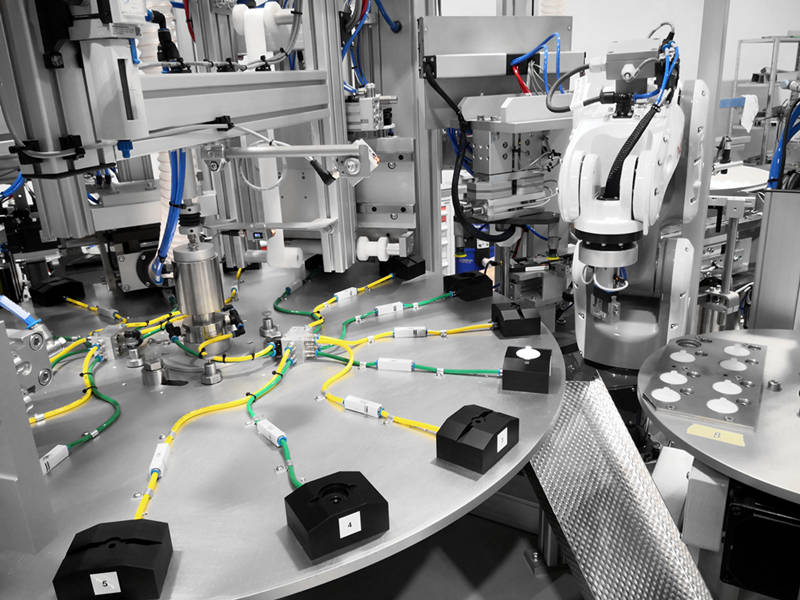

The automation solution is based on an indexing rotary table to transfer products between the various process stations. The machine is designed for quick changeover between products without the use of tools. The changeover procedure is largely automatic selectable from the HMI. Change parts are designed for quick and simple changeover with sensors checking for the correct setup configuration, allowing running of two variants with future proof upgrade capabilities.

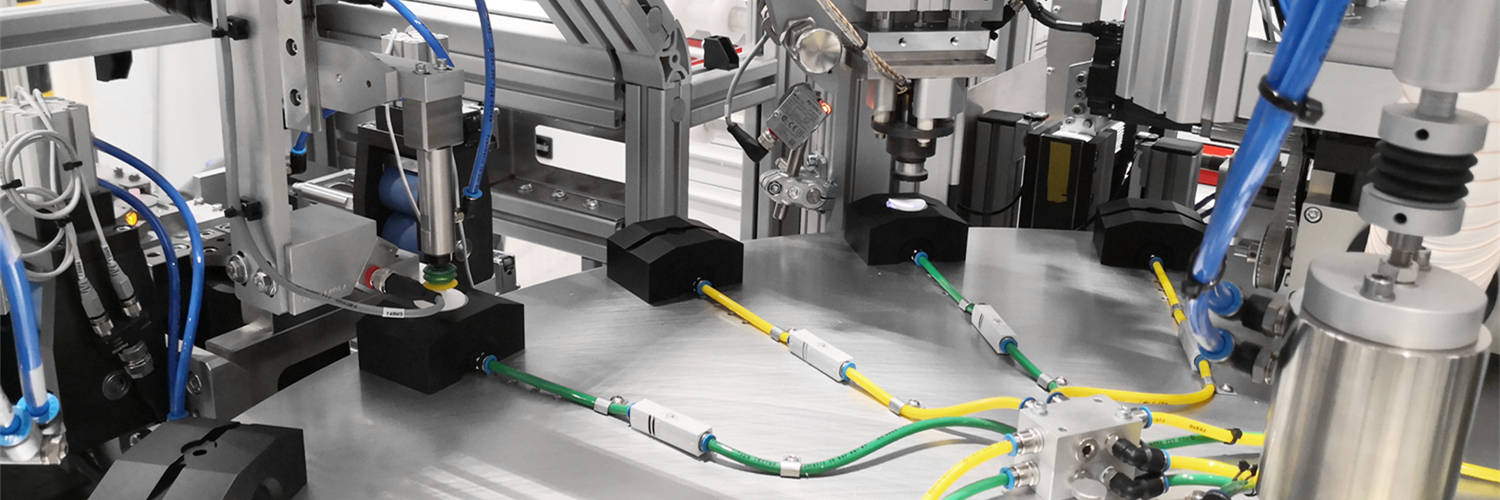

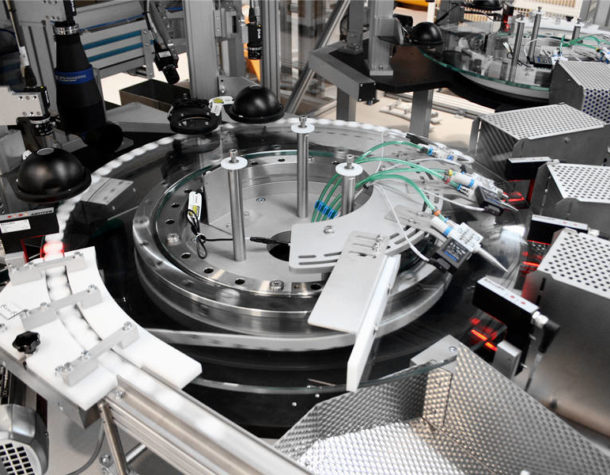

Rotary Table & Nests

8 station rotary index machine; The rotary table is fitted with two sets of tooling nests, one set for 13mm products and one set for 30mm products.

Operation Sequence

Spare station for future proof upgrade capabilities

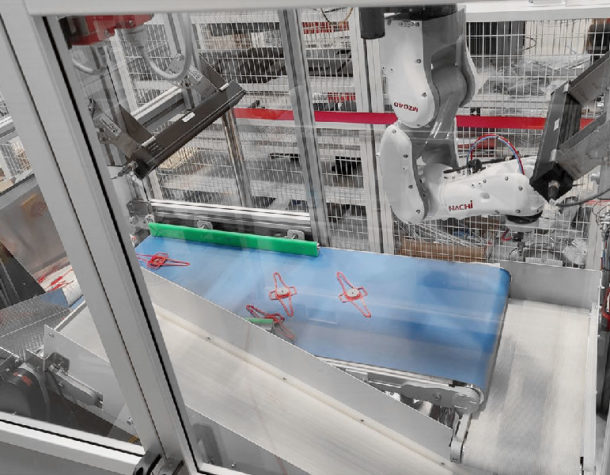

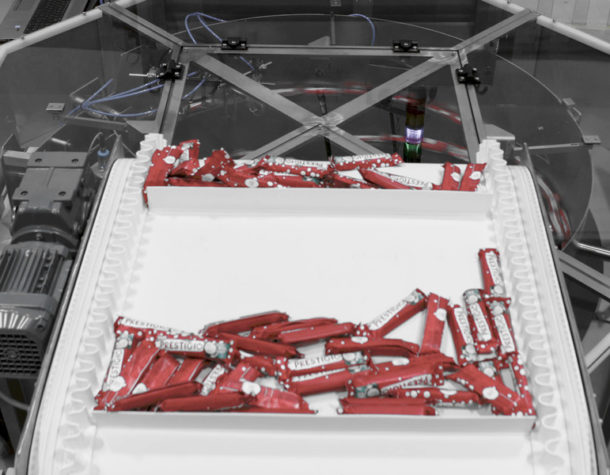

APL Skills

Machine building and integration, Machine and process control, Bespoke assembly machine, Rotary indexing tables, Feeding and handling, Pick and place, Project management